The Rainscreen Group, formed from companies within MCRMA membership, includes the principal companies who supply metal based systems and component parts used within the fabrication and construction of rainscreen cladding systems.

Members of the group have been involved in the development of rainscreen systems over many years and have an extensive knowledge of their use and application on all types of buildings. In addition, the rainscreen group provides a technical focus for specifiers who wish to use these highly aesthetic systems on prestigious new build developments or refurbishment projects.

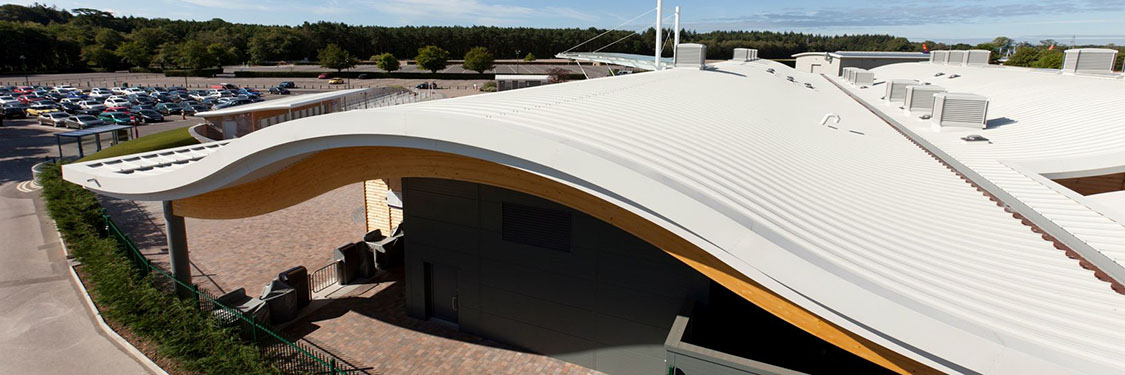

The technology used within modern rainscreen systems provides a weather skin which can be attached to an existing wall or new sub-structure and allows the incorporation of insulation systems which comply with the latest energy efficiency standards and building regulations. Rainscreen systems also offer specifiers and building owners the opportunity to explore the use of colour and scale to provide a visually exciting or contrasting façade.

A new MCRMA guidance document, GD39 Sustainability and durability of metal roofing and cladding systems focuses on sustainability from a ‘fabric first’ approach where the metal building envelope provides a long-lasting solution which can be future proofed for potential changes of use of the building. As there is a natural split between sustainability and durability topics the MCRMA guidance document is published as a suite of eight standalone sections each of which covers specific but interrelated subjects, including sustainability background, zero avoidable waste, environmental assessment methods, durability, life cycle/whole life costing, products and components. The document can be downloaded from the sustainability page.

A new guidance document, GD40 Understanding membranes in ventilated rainscreen facades takes an holistic approach to the key elements of design around airtightness, water ingress, condensation control (vapour permeability), and fire protection to achieve the optimum performance and long-term durability in ventilated rainscreen facades.

MCRMA has issued an Advice Note which sets out how specifiers can comply with the ‘combustible ban’ Building (Amendment) Regulations 2018. This Advice Note provides specifiers with information relevant to the specification of A2 powder coated materials.

In recent years the UK building envelope industry has witnessed the introduction of magnesium oxide (MgO) boards into the cladding sector, most typically as the sheathing board on steel framing system (SFS) backing walls. MgO has been favoured because it is non-combustible (typically class A1 to EN 13501-1), relatively lightweight and easy to cut.

However, there are a number of manufacturing processes by which MgO boards can be manufactured, one of which involves the use of magnesium chloride. This results in an end product (sometimes referred to as magnesium oxychloride) in which there may be variable amounts of chloride salts and free chloride ions. More information about MgO boards and the use of MgO boards is available from the Canadian Construction Materials Centre (CCMC), the Centre for Window and Cladding Technology (CWCT) and British Standards Institute (BSi). Documentation on this subject can be downloaded via the links opposite.

Members of the Rainscreen Group speak with authority on the subject, provide support based on years of knowledge and give reliability in the systems they supply and manufacture. Information about member companies can be obtained by clicking on the individual company links opposite.