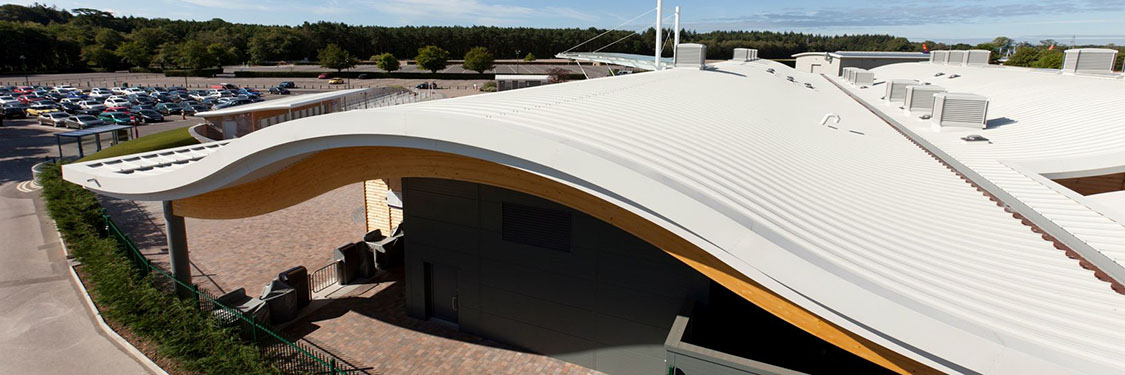

Metal based roofing and cladding is the primary product for the industrial, commercial and warehouse sector plus associated sectors such as the agricultural and rural building market. In addition, a systems-based design approach can provide envelope solutions for stadia, concert halls, sports arenas and transport hubs together with large open space distribution centres and environmentally controlled spaces.

Pre-coated profiled steel and aluminium and self-finished material is widely available in a range of different profiles and aesthetic colours and finishes to suit every application. Trapezoidal profiles are the most widely used across the sector however, system manufacturers also offer the traditional sinusoidal profile which was widely used in agriculture but is now becoming popular for buildings requiring the retro look. Standing seam and concealed fix profiles are also widely used and offer long ridge to eaves options without the need for a through fix installation. A number of system manufacturers also roll-form specialist profiles which provide enhanced aesthetics for wall applications. A wide range of options can be found on the MCRMA product selector.

Guidance document GD 32 Self drilling fastener installation tools explains that screw guns are an installer essential when working in roofing and cladding construction, as they ensure that the optimum mechanical performance of a self-drilling fastener is obtained, guaranteeing the integrity of the building envelope. Impact drivers should not be used! Their repetitive impact action can lead to drilling failures, reduce the fastener pull-out performance, and damage the coating or strip the moulding on the fastener head.

Metal based profiled roofing and cladding offers a quick and cost-effective solution for both new build and refurbishment projects. Single skin, twin skin and sandwich panel products and systems provide the design team and end users with the opportunity to tailor solutions to meet current building standards and exacting environmental and sustainability criteria.

A new MCRMA guidance document GD39 Sustainability and durability of metal roofing and cladding systems focuses on sustainability from a ‘fabric first’ approach where the metal building envelope provides a long-lasting solution which can be future proofed for potential changes of use of the building. As there is a natural split between sustainability and durability topics the MCRMA guidance document is published as a suite of eight standalone sections each of which covers specific but interrelated subjects, including sustainability background, zero avoidable waste, environmental assessment methods, durability, life cycle/whole life costing, products and components. The document can be downloaded from the sustainability page.

Metal based profiled roofing and cladding products and systems from MCRMA members comply with BS EN 14782:2006 Self-supporting metal sheet for roofing, external cladding and internal lining. Product specification and requirements and composite panel products comply with BS EN 14509:2013 Self-supporting double skin metal faced insulating panels. Factory made products. Specifications. These harmonised standards form the basis for product CE marking across European markets together with the UKCA mark and the UK(NI) mark.

From the design phase of a building through to operational use BS 5427:2016 + A1:2017 Code of practice for the use of profiled sheet for roof and wall cladding on buildings, which also refers to the other associated components, should be referenced to ensure compliance with the latest thinking on the subject.

The MCRMA and member companies provide technical and commercial support based on many years of experience within the sectors and detailed involvement in the development of both National and European standards.

The specification of single skin, twin skin and composite roofing and cladding products and systems rely heavily on the integration and use of associated component parts such as rooflights, fasteners, insulation, sealant, flashings and fabrications plus gutters and support structures along with other specific elements. Compatibility between all of the component parts is paramount to ensure a functional and operational roofing and cladding system with recognised guarantees and warranties through the life cycle of the building.

The membership structure of the MCRMA recognises the need for the incorporation of these other elements into the final design together with the involvement of system installers, design specialists and project specific inspectors.