Page 3 - MCRMA Metal Matters Oct 2022

P. 3

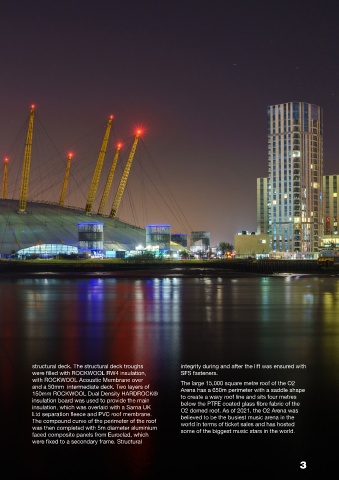

Protecting the Sound

at the O2 Arena

The O2 Arena in London was built under the The complex roof design features several layers structural deck. The structural deck troughs integrity during and after the lift was ensured with

former Millennium Dome and opened in 2007. of different density barrier materials to deaden were filled with ROCKWOOL RW4 insulation, SFS fasteners.

The domed roof of the indoor venue is now a even the lowest bass frequencies, all carried with ROCKWOOL Acoustic Membrane over The large 15,000 square metre roof of the O2

well-known London landmark. on special acoustic deck structures. An added and a 50mm intermediate deck. Two layers of Arena has a 650m perimeter with a saddle shape

challenge was that the roof had to be built up 150mm ROCKWOOL Dual Density HARDROCK®

As the O2 Arena regularly hosts large concerts, to create a wavy roof line and sits four metres

acoustics were a major factor determining the at ground level and then jacked into place, four insulation board was used to provide the main below the PTFE coated glass fibre fabric of the

design and construction of the roof. Not only metres under the existing fabric roof. insulation, which was overlaid with a Sarna UK O2 domed roof. As of 2021, the O2 Arena was

was it important to safeguard the sound quality To achieve the best possible acoustic Ltd separation fleece and PVC roof membrane. believed to be the busiest music arena in the

for audiences of tens of thousands inside, local performance, fully perforated aluminium The compound curve of the perimeter of the roof world in terms of ticket sales and has hosted

residents and visitors to the area outside had to be acoustic trays were filled with ROCKWOOL was then completed with 5m diameter aluminium some of the biggest music stars in the world.

protected from all nuisance ambient noise (bass RW6 insulation, cut to profile and faced faced composite panels from Euroclad, which

thumping) permeating the roof of the building. with black tissue and supported on 200mm were fixed to a secondary frame. Structural

2 3